I was born in Southern California, in the San Fernando Valley. I grew up in a home with a loving mother and father. While I was growing up, I saw very little of my father, who worked long hours – going to work before I got up and coming home after I was asleep. But once a year, on his two-week vacation he would pack us all up – my older brother, my mom and me – in an Alaskan camper and take us camping. Sometimes we would go to the mountains, but usually we would go to the desert. These camping trips were my best childhood memories.

I was born in Southern California, in the San Fernando Valley. I grew up in a home with a loving mother and father. While I was growing up, I saw very little of my father, who worked long hours – going to work before I got up and coming home after I was asleep. But once a year, on his two-week vacation he would pack us all up – my older brother, my mom and me – in an Alaskan camper and take us camping. Sometimes we would go to the mountains, but usually we would go to the desert. These camping trips were my best childhood memories.

When I was 12 my dad bought a Honda 90 trail bike and he bought my brother and I both Taco min-bikes with 5 horsepower Briggs and Stratton lawn mower engines in them. He got them at the lawn-mower shop. We had fun visiting old ghost towns and mining towns – riding around on our new mini-bikes. We went to Carson city, Bodie, Ridgecrest, and Red Rock Canyon.

During that period of my life, when we weren’t camping, I would ride my mini-bike in the hills around our house and wherever there was new home construction. After school, we would ride up the terraces where there were housing tract developments.

One time I decided to remove the muffler on my mini-bike and replace it with a straight pipe. Then I started experimenting with different lengths of water pipes – shorter and longer. I learned that the longer pipe worked better – it seemed to my 12 year-old mind to give me more power. Since it was a straight pipe, I was told I should cap the end, to keep the exhaust valve from warping. So I carried around a pipe cap in my pocket to protect my engine!

One time I decided to remove the muffler on my mini-bike and replace it with a straight pipe. Then I started experimenting with different lengths of water pipes – shorter and longer. I learned that the longer pipe worked better – it seemed to my 12 year-old mind to give me more power. Since it was a straight pipe, I was told I should cap the end, to keep the exhaust valve from warping. So I carried around a pipe cap in my pocket to protect my engine!

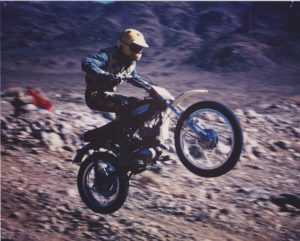

When I was around 15 years old my dad bought my brother and I Yamaha AT-1 125cc motorcycles. And my dad bought himself a DT-1 250cc motorcycle. So then we started riding in the desert with these. Our local Yamaha dealership’s mechanic – Glen Bolenbaugh – got us interested in racing. So we stripped off our lights and mirrors, and went to the races. Glen got us signed up in the AMA – District 37 motorcycle races. Glen was a member of the Antelope Rambler’s Motorcycle Club. We or course wanted more power for our motorcycles. So I started experimenting again – this time with 2-stroke engine’s exhaust systems. I started making ‘pipes’ for friends, and then friends turned into customers.

During those years, in the early ’70’s – the first thing that a racer would do with a new motorcycle, is to replace the stock exhaust pipe with a “turned” pipe. So I bought a couple of pipes and put them on my motorcycle to see how they would affect my power. This began my captivation with the science of exhaust-tuning. I had to find out what made them work.

Back in those days, there wasn’t very much information available about engine timing in general. (No Google!!) I did locate a book out of England – which I sent for. I pored over that book from cover to cover – many times, as I tried to grasp the concepts of harnessing exhaust energy.

During these high school years, there was a defining person who stands out in my memory. It was Mr. Lee Deneen, my metal shop teacher. Mr. Deneen was a tall, thin welding expert – who wore a lab coat to class. He caught my attention and respect by the way he interacted with us and showed his interest in us. After demonstrating for us safety practices with an oxy-acetleen welding outfit, he pretended one of the valves was stuck closed. He ‘tried really hard’ opening it and when he did manage to get it open, he surprised everyone by cracking an air popper – startling us and really getting our attention! I was amused at his humor in his soft-spoken way. In that class Mr. Deneen taught us more than metal working. He taught us values and the importance of doing a job thoroughly and completely. I learned the skill and art of gas welding and later with on-the-job training. I was employed at Mid Valley CZ motorcycle Shop – welding exhaust pipes. So in my free time I started experimenting again with exhaust pipes – building them for myself and my friends. I kept studying and searching publications for information on engine tuning.

I found Gordon Jennings book – – and that that became my standard. His book explained relationships between lengths, diameters, angles, volumes and their relationship with horsepower and torque.

I started to design exhaust systems in a more scientific way, instead of randomly trying different things. When I got those books, I had some formulas to work with. When I used the formulas and applied them to my pipes, I started getting very positive results.

I started to design exhaust systems in a more scientific way, instead of randomly trying different things. When I got those books, I had some formulas to work with. When I used the formulas and applied them to my pipes, I started getting very positive results.

I remember one time Jack Crisman told me to put a 1/8” larger head pipe on my Harley Baja. Wow, what a difference that made in power!

In my late twenties I opened my own welding shop.

While I took on a lot of different work, it was here that I also transitioned into designing exhaust systems for 4-strokes. I worked on circle track cars, off-road trucks, and speedway motorcycles. I was one of the first to use the stepped-header design.

When I got into 4-stroke exhaust design, that’s when I began making mufflers.These custom made, hand built, one-off mufflers were highly successful, – they made the engines quieter, without losing power.

I started working with speedway motorcycles and I met a man named Richard Parbock. I had been told that this was a person that lived not too far from me that had experience with methanol fuel. He had built the off-road engines for Ford, Stadium and Baja trucks. I casually mentioned to him that if he needed someone to build and exhaust for his stadium truck, I would be interested. “Sure”, he replied. After getting the engine specifications, track conditions and driver’s style, we tested the system – complete with muffler at the Glen Helen Raceway. Wow! It works good, has a better throttle response, it’s quiet – we like it! Then I found out that people usually just work for free for these types of racing engines, and I decided to put that on hold.

Country living in Idaho

We moved to Idaho from Southern California and that brought us to the jet-boat capital of the country, just one hour away. Jet-boats have 4 stroke engines! So we started making mufflers for jet boats. These boats are like motorcycles – there is just no room for any good size muffler. So that’s why I found out they are so loud. We’re trying to silence a 400+ HP engine with 2 pop cans. When I visited with one of the jet boat manufacturers they said – we know they don’t work – but we point to the muffler and tell the customer – there’s your muffler. Hmmm.I started making mufflers for Weldcraft. They were gracious enough to give me their time and do testing of my mufflers in their boats. They tested for RPMs and decibels – both in the boat and on the shore.

They were happy with my muffler design and I became their sole supplier for two years. When they joined with Duckworth, I made mufflers for the Duckworth line as well.

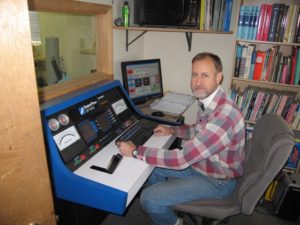

Byron Dyno testing

This business relationship came to an end when a different supplier offered them a lower pricee. I was told, “We know yours are better, but these are cheaper.” And then he asked me if I could make mine as cheap as their’s. I replied, “no, mine are three times the work to build compared to the competitor’s”.

Meanwhile, I continued the welding shop, and put the mufflers on the back burner. About 6 years later I made a prototype muffler for Riddle Marine. They were interested but too busy at first to test. In the meantime, Marty from Kodiak Marine engines saw the mufflers and wanted to test them. After the testing, his description of the mufflers was one word – “Phenomenal”. He said, “In 35 years of being in this business, I’ve never tested a muffler that worked as good as this one.” After that Riddle Marine began enthusiastically ordering them to install on their boats. Up until this point I hadn’t had my own marine engine to do my own in-house testing.

burner. About 6 years later I made a prototype muffler for Riddle Marine. They were interested but too busy at first to test. In the meantime, Marty from Kodiak Marine engines saw the mufflers and wanted to test them. After the testing, his description of the mufflers was one word – “Phenomenal”. He said, “In 35 years of being in this business, I’ve never tested a muffler that worked as good as this one.” After that Riddle Marine began enthusiastically ordering them to install on their boats. Up until this point I hadn’t had my own marine engine to do my own in-house testing.

The acquisition of a marine engine completed Thorpe Engine Development’s Marine Research and testing capabilities.